Automatic Compact Busduct Production Line Self Percing Riveting System Busbar Machine

Automatic sandwich busduct production line / Automatic self piercing riveting system for compact busway systemThe automa

Basic Info.

| Model NO. | KDEQ-E-21-001 |

| Trademark | Kiande |

| Origin | China |

| Production Capacity | 10 Sets Two Months |

Product Description

Automatic sandwich busduct production line / Automatic self piercing riveting system for compact busway systemThe automatic busbar assembly line is used to automatically assemble clamp, rivet the aluminum enclosure.This assembly line is for two-piece type busduct system.If four-piece type busduct, this automatic busbar assembly line need to work together with manual assembly line, to rivet the other side of four-piece type busbar.In addition, we have another type of automatic busbar assembly line for both two piece busduct and four piece busduct.Specification:| No. | Parameters |

| Model | KD-ZDX/NC-2(4)D-6(4.5) |

| Max. Busbar Height | 350mm (Single layer) |

| Max. Busbar Length | 6000mm |

| Position Type | Unilateral position/ Middle position |

| Working Efficiency | Around 3000 mm/2 min |

| Control Axis | 5 Axis |

| Control System | Network control, Online maintenance (optional) |

| Riveting Station Nos | 4 sets (Four-piece type)/2 sets (Two-piece type) |

| Riveting Type | Automatic riveting |

| Power | 380~415VAC 50~60Hz 20kW |

| Equipment Dimension | L25000mm*W2000mm*H19000mm |

We are the company specialized in busbar machine.Busbar machine means busbar production machine or busbar processing machine including mylar sleeve forming machine, busbar assembly machine, busbar riveting machine, busbar testing & inspection machine, busbar packing machine and busbar conveying machine. If you want to know how we use the machine to assemble the busbar, please kindly get the referenced pictures as below.

Step 1 Prepare all busbar finished components

Step 2 Use related busbar machines to process the busbar

Busbar machine copper processing

Need Kiande's busbar gas-hydraulic copper bar punching machine(This is one-time punching forming. In the market, some busbar manufacturer buys three-in-one busbar machine to bend and punch copper or aluminum bar. As the bar experiences many procedures, the accuracy is not good which will cause the phase distance too small to cause the short circuit.)

Busbar machine mylar sleeve processing machine polyester film forming machine

Need Kiande's mylar/polyester film forming machine. In the market, some busbar manufacturer requests workers to wrap the bar manually. Different workers have different workmanship. If employer meets the inexperienced workers, the wrapping part will have some gaps which will cause the short circuit.

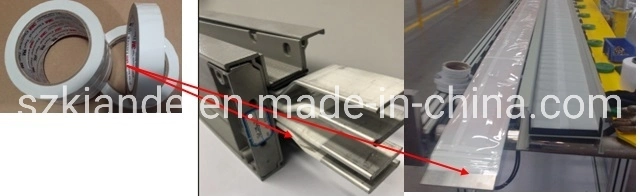

Busbar machine busbar accessory 3M insulation film Conductor(Copper bar/Aluminum bar) end wrapping

Busbar machine busbar accessory Aluminum profile capped casting capped end

Busbar machine Busbar riveting machine

Busbar machine busbar inspection machine busbar testing machine

Busbar machine busbar packing machine busbar packaging machine

Busbar machine busbar accessory rivet the rivet is to connect the profiles instead of bolts more stable and strengthen

Busbar machine busbar accessory joint isolator

Send to us